- 01 About DECO

- 02 Product Center

- 03 DECO Solutions

- 04 DECO Solutions

- 05 Join Us

- 06 Contact Us

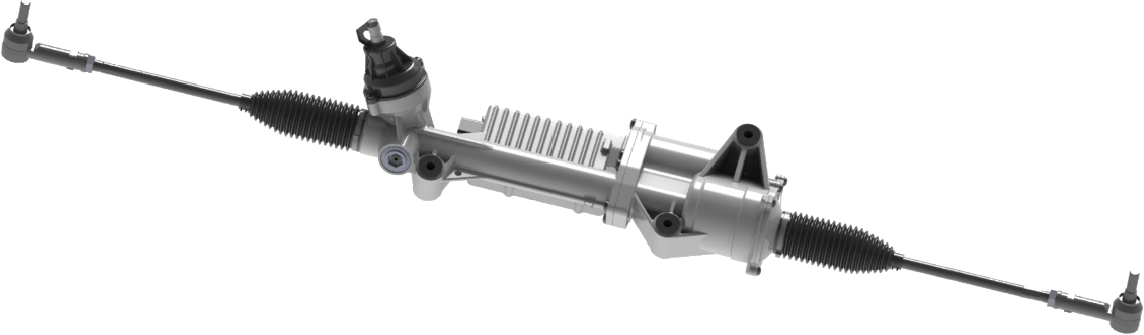

The motor of R-EPS is installed on the rack, and the power directly acts on the rack. The deceleration mechanism of R-EPS is belt drive mechanism and ball screw pair.

At present, R-EPS is mostly used in luxury models such as BBA, Porsche, and Crown, as well as medium-large size SUVs and commercial vehicles with front axle weight over 1.5 tons, such as Ford F150 and Transit.

The output force is large. Since the bearing capacity of the ball screw drive system is much larger than the worm & gear and pinion & rack structure, the output force of R-EPS is much larger than that of DP-EPS, which can reach 16000N

Low noise, smooth hand feeling, and high precision. The motor of R-EPS is away from the steering column, and its cogging torque is difficult to transfer to the steering wheel. In addition, there is no torque fluctuation caused by gear meshing in ball screw transmission, so the hand feeling of R-EPS is very smooth. And the operation noise of ball screw pair is lower than the rack & pinion, transmission accuracy is higher than the rack & pinion, so that R-EPS has smooth hand feeling, excellent noise performance and transmission accuracy

High transmission efficiency. R-EPS uses belt and ball screw pair to achieve two-stage transmission. The efficiency of belt transmission can reach 95%, while the ball screw transmission can reach 90%. The overall transmission efficiency of the system is up to 85%, higher than other types of EPS system.

Provide multiple assistant modes such as Active-return, high-speed damping, temperature protection, end protection, as well as control functions such as off-hand monitoring and body stability.

Meet the SAE Levels of driving automation L2.5 and can realize intelligent steering functions such as LKA, TJA and APA

Meet the requirement of Automotive Safety Integrity Level 26262